![]() Three

production cells

Three

production cells

![]() On-screen process information for - easier

On-screen process information for - easier

maintenance less down time - higher production

quality

![]() User-friendly programmable software

User-friendly programmable software

![]() Stand-alone system

Stand-alone system

![]() Designed for superior TTV (Total Thickness Variation) for

Designed for superior TTV (Total Thickness Variation) for

future formats.

![]() New

powerful processor for additional software

New

powerful processor for additional software

The

AQUARIUS Electroforming has features that really help the operator

maintain a high productivity and quality level. On-screen process

monitoring gives the operator information exactly when filter cartridges

need changing, nickel pellets have to be replenished and when anode

baskets need cleaning. No random inspection. No emergency stops. No

waste of material. No spoiled stampers. Just consistent high quality

production with a minimum of down time. The system is controlled by a

PLC which is designed for industrial use to ensure high reliability.

User programmable recipes have high repeatability. The cabinet is fully

contained with all components within the footprint area. This also gives

flexibility of location.

Automatic

passivation for full family making

![]() Automatic Cathodic/Anodic cleaning

Automatic Cathodic/Anodic cleaning

![]() Automatic cleaning of used stampers

Automatic cleaning of used stampers

![]() Pat. pending self locking spin chuck for low and high

Pat. pending self locking spin chuck for low and high

speed spinning

![]() Workbench

for work holder preparation

Workbench

for work holder preparation

![]() Work

holder storage

Work

holder storage

![]() User-friendly

programmable software

User-friendly

programmable software

![]() Stand

alone system

Stand

alone system

Polaris has features that really help the operator maintain a high

productivity and quality level. Many time-consuming functions have now

been made automatic.

On-screen process monitoring gives the operator information about the

process parameters. Users programmable recipes insure good process

repeatability. The station has built-in HEPA class 100 filters that

eliminates dust particle contamination.

The cabinet is fully contained with all components within the footprint

area. This also gives flexibility of location. Just consistent high

quality production with a minimum of down time. Anodic passivation,

cleaning, rinsing and chemical spin processes is all automatic. The user

can make his own programs in any combinations.

10 programs with 10 steps for each process.

Fully automatic back polishing process with up to three different grades of finishing discs available.

harmful.

This

machine greatly improves operator environment by eliminating all harmful

polishing dust particles from the air. Orion is PLC controlled with

software adjustable process parameters. A colour touch screen user

interface makes it easy to operate

ORION features that really help the operator maintain a high

productivity and quality level. On-screen process monitoring gives the

operator information exactly when filter cartridges need changing,

polishing pads have to be replenished and when nickel sludge container

needs cleaning.

No random inspection. No emergency stops. Just consistent high quality

production with a minimum of down time.

The system is controlled by a PLC which is designed for industrial use

to ensure high reliability. It has user programmable recipes.The cabinet

is fully contained with all components within the footprint area.This

gives flexibility of location.

![]() Nuclear grade ion polisher for optimal quality

Nuclear grade ion polisher for optimal quality

![]() UV filter for sterile distribution

UV filter for sterile distribution

![]() Easy installation

Easy installation

![]() Fully automatic

Fully automatic

![]() Safe and cost effective operation

Safe and cost effective operation

![]() Small footprint

Small footprint

![]() Expandable for increased capacity

Expandable for increased capacity

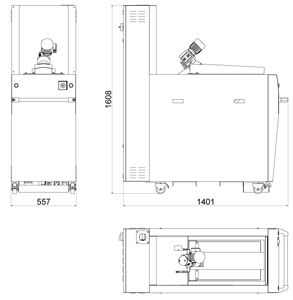

Electroforming unit

True stand alone unit

Movable on wheels

One production cell

Designed for superior TTV

Easy access for production and maintenance

Internal PLC Controller

Suitable

for different types of electrolyte,

such as Ni, Cu, e.t.c.

Easy adaptable for automatic production.